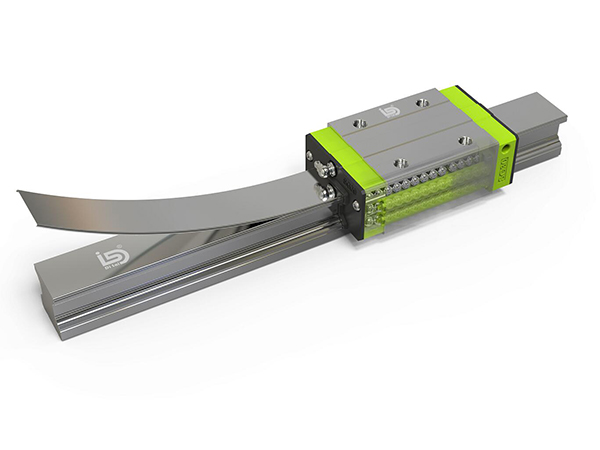

*Feature: Super heavy load, Dust proof. e.g Our grinder is using this series*

The SG series linear guides have moment load capacities higher than standard LDH series.

The O-Type (back-to-back) bearing configuration and an integrated recirculation unit optimize bearing circulation greatly improving moment load capacities and promoting smooth motion.

An optional stainless steel cover strip increases dust protection and promotes smooth block transition.

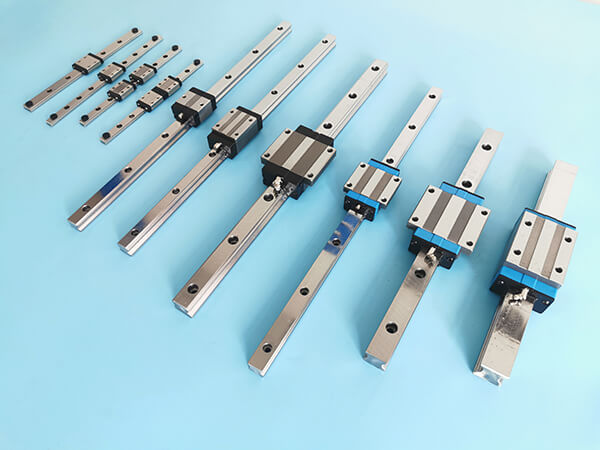

*Feature: Interchangeable with HG, compatible with most other brands, widely used by various industries*

Standard linear guide rails and blocks have competitive price and reasonable quality. They are suitable for less demanding applications and are interchangeable with HG products with linear block and linear guide rails made in C-normal accuracy, zero, light and high preload.

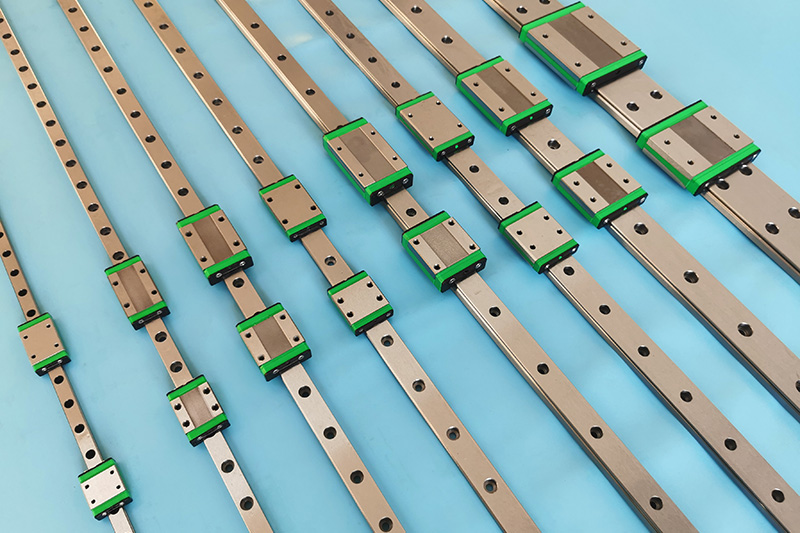

*Feature: Interchangeable with MGN, compatible with most other brands*

Miniature linear guide provide precision low friction guidance of preloads for machine and instruments applications. One or multiple bearing blocks can be mounted on a linear guide rail.

There are also options for standard, wide and longer block. Three different accuracy grades are available, C grade, H grade, and P grade.

These products are available in industry standard sizes as small as size 7 up to size 15. Rail length up to 2000mm long.

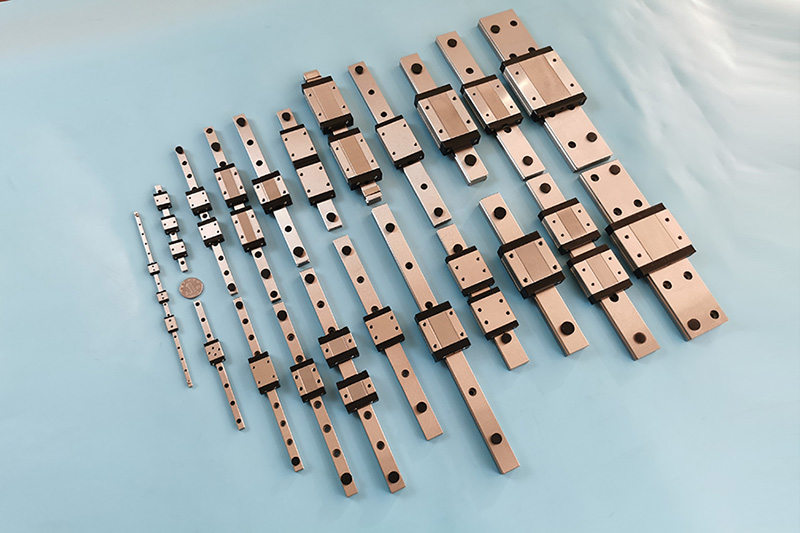

*Feature: Corrosion resistant*

The linear guide block and linear guide rail are made of 440C stainless steel.

There are also options for standard, wide and longer block. Three different accuracy grades are available, C grade, H grade, and P grade.

These products are available in industry standard sizes as small as size 3mm up to size 15mm. Rail length up to 1500mm long.

*Feature: Interchangeable with RG, high rigidity, well-balanced load, high precison*

The SR series roller linear guide features a roller as the rolling element instead of steel balls, each row of balls is placed at a contact angle of 45.

A ball provides a single point contact area, while a roller provides a much greater line contact area. This results in a substantially higher load carrying capacity and lower wear with minimum rolling friction.

Roller guide is available in H and P precision classes, and is interchangeable or compatible on standard H precision classes.

SR roller linear guides offers high performance for high-precision manufacturing and achieving longer service life, are ideal for industries like machine tools, automation, plastic injection molding or material handling.