A: In most cases, the rail and block mounting dimensions are the same. Block size might have slight differences. Please verify both our compatible chart and other manufacturer’s catalogue for more detail information.

A: Yes can be added or replaced with Interchangeable Linear Guides. For example at normal precision, LDH series linear guides are interchangeable to HIWIN’s HG series linear guides, ball screws are interchangeable to TBI’s products.

A: All non-interchangeable types of linear guides and ball screws are sold as a set, with blocks mounted on rail or nuts mounted on screw shaft, and precision standard is only guaranteed for original purchased set.

A: For LDH standard series, black and red; For SG series, blue and black.

A: We can provide miniature linear guide made of stainless steel.

A: No. The nut and the screw need to be adjusted before they can be paired. The requirements for preload and clearance are achieved by adjusting the steel balls.

A: JIS grade accuracy for example C3, C5, C7, C3=0.008, C5=0.018, C7=0.05 (mm)

Our factory accuracy grade for example P2, P3, P4, P2=0.008, P3=0.012,, P4=0.016, P5=0.02 (mm)

**P3 accuracy means the positioning error of any 300mm effective stroke is ±0.012mm

A: The standard number of turns for a C7 rolled ball screw is T4 and T8. C3, C5 grinding ball screw turns can be customized

A: Yes both metal and plastic material available

A: Re-lubrication is not necessary, as we will apply lubricating oil before the products leave the factory.

A: In order to protect the goods from bumps, we provide fumigation-free Laminated Veneer Lumber packaging.

A: Plastic rails are mounted on block (carriage).

A: We provide blackening surface treatment.

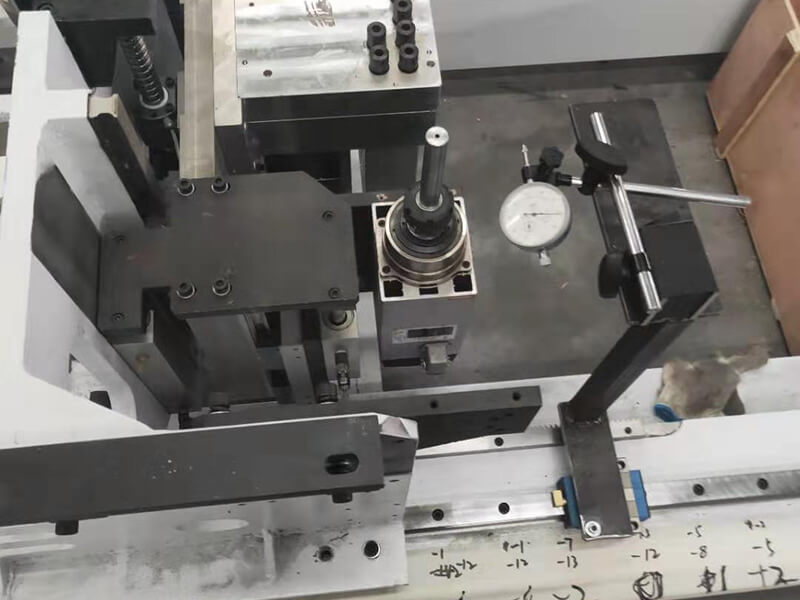

A: We have a laser detector to test the accuracy of the ball screw, and a test report can be issued with an accuracy of ≤0.012 mm

A: Please refer to table in ball screw detail page.

A: Yes. ACME screw is made of 45# steel or stainless steel. The surface treatment is black chrome plating at low temperature, and the accuracy level can reach 7E/7H.